Possible coronavirus drug: university pharmacists produce generic medication

In response to a lack of potential coronavirus medications on the market, pharmacists from the University of Basel have begun to produce tablets themselves. Chronic patients, among others, could benefit from this.

The active substance with the somewhat unwieldy name of hydroxychloroquine is considered a potential drug for the prevention and treatment of Covid-19. Its suitability for this purpose is currently the subject of several ongoing clinical trials.

Regardless, a race is currently underway to obtain the active ingredient. India, one of the largest producers, had for a time banned exports of the drug. It was only after threats from the US president, who described the drug as a game changer, that India again approved its export, albeit in limited numbers.

Hydroxychloroquine has anti-inflammatory, immunomodulatory, and antiviral effects. Although predominantly an antimalarial drug, it is also used in the treatment of rheumatic disease in Switzerland. Under normal conditions, the active substance is commercially available in the form of coated tablets, but the international market of these tablets has dried up due to hopes that the drug will have a positive effect on the treatment of Covid-19. This is a particular problem for patients who rely on it to for the treatment of chronic rheumatic diseases.

Generic medication from the research lab

To overcome this supply bottleneck, a team of scientists from the University of Basel led by Dr. Maxim Puchkov have begun to manufacture the tablets on their own. According to Professor Jörg Huwyler from the Department of Pharmaceutical Sciences, they succeeded in obtaining 50 kg of hydroxychloroquine sulphate from a Swiss supplier “at the last minute”. Some of the active substance was supplied to German hospitals as an emergency measure, and 40 kg of the remaining material is now under the control of the Federal Office for National Economic Supply.

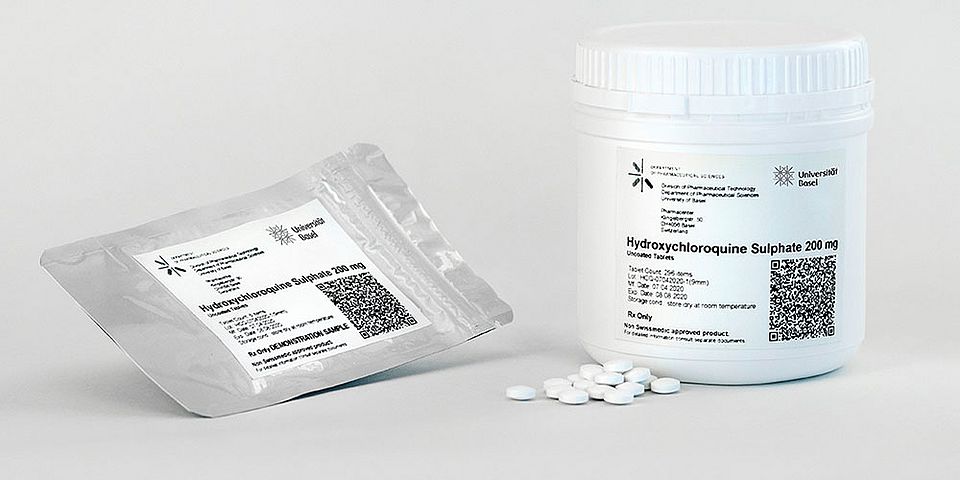

In the meantime, the researchers in Basel have developed a pharmaceutical procedure to manufacture tablets that can be administered orally. “In the space of 10 days, my team has essentially produced a generic medication,” says Huwyler. The pharmacists have prepared an initial batch of 4,000 tablets, which would be enough to treat 400 patients. These tablets are currently being held in reserve at the hospital pharmacy of University Hospital Basel. In total, the available quantity of active substance could be used to produce 200,000 doses – enough for 20,000 patients. The production protocols will soon be made freely available in the form of a scientific publication.

According to Huwyler, hydroxychloroquine is already being used experimentally in Switzerland to treat hospitalized patients with severe cases of Covid-19. However, given the limited availability and the risk of serious side effects, doctors have been very reluctant to prescribe the drug.

“We hope that our production will help overcome the current bottlenecks in Switzerland’s supply,” says Huwyler. This would also relieve the situation for chronic patients in need of this treatment. The question of where the tablets produced at the University of Basel are eventually used is up to the regulatory authorities, which will decide on the future production and distribution to Swiss hospitals.

Original source

Tomaž Einfalt, Pascal Detampel, Daniel Häussinger, Jens Casper, Christoph Meier, Jörg Huwyler, Maxim Puchkov

Hydroxychloroquine immediate release tablets: Formulation and evaluation of a solid dosage form

Publication in preparation

Further information

- Prof. Dr. Jörg Huwyler, University of Basel, Department of Pharmaceutical Sciences, tel. +41 61 207 15 13, email: joerg.huwyler@clutterunibas.ch

- Dr. Maxim Puchkov, University of Basel, Department of Pharmaceutical Sciences, tel. +41 61 207 16 19, email: maxim.puchkov@clutterunibas.ch